THE Q4 CLIFF

For Hickory Farms, the stakes are binary: Make the year in Q4, or fail. Managing 200+ pop-up stores creates a massive inventory risk. If high-demand product sits in a low-traffic kiosk while a flagship store goes out of stock, that revenue is lost forever. Leadership lacked real-time visibility into 'Stock-to-Sales' ratios, leading to missed opportunities and reactive panic shipping.

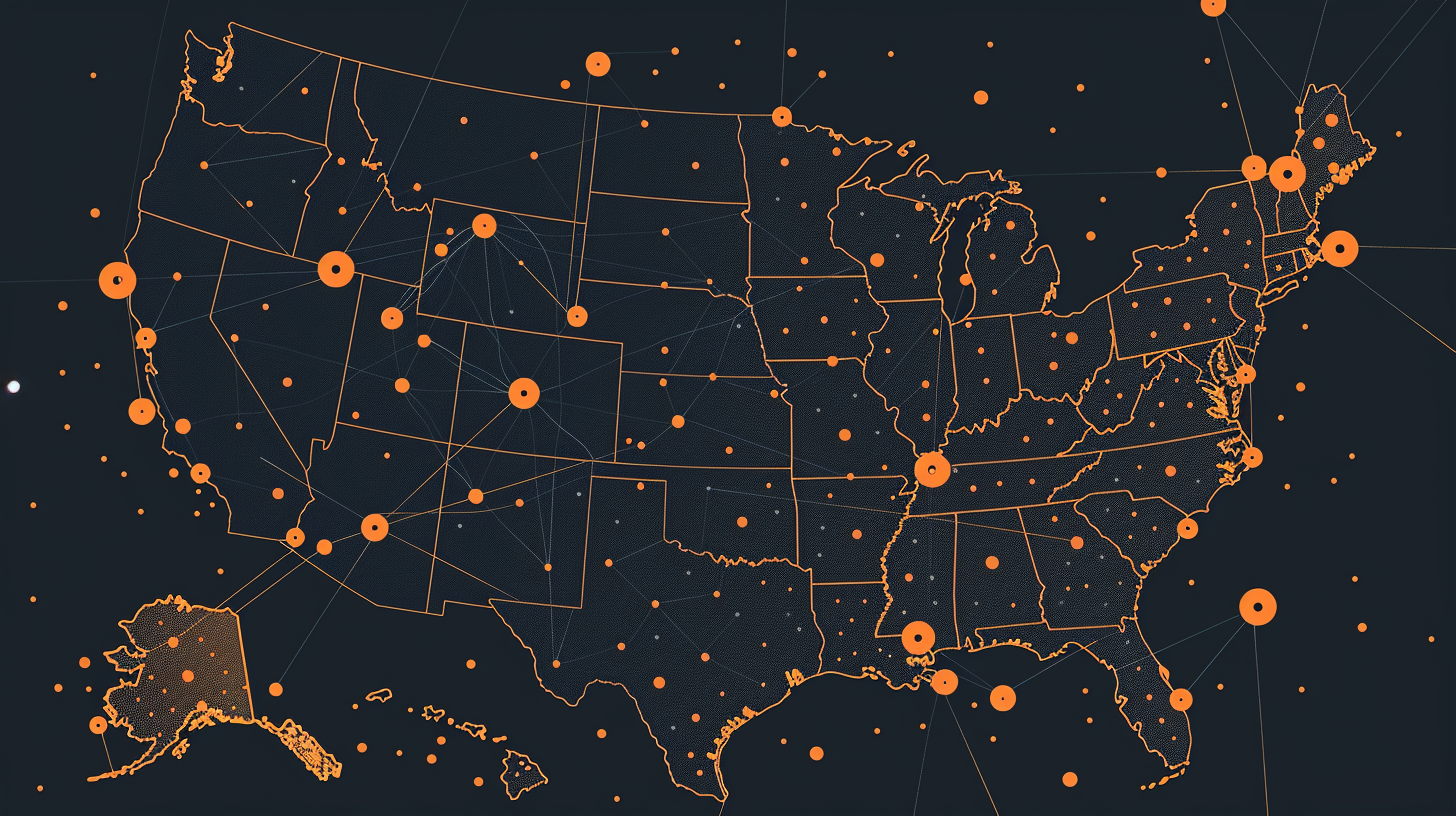

THE ARCHITECTURE

We engineered an Inventory & Revenue Command Center to align stock levels with sales velocity in real-time.

- Revenue Normalization (SPSD): We used 'Sales Per Selling Day' to identify high-velocity locations immediately, stripping away the noise of staggered opening dates.

- Inventory Balancing Protocol: We built logic to visualize 'Weeks of Supply' at the store level. This highlighted imbalances instantly—showing where inventory was hoarding vs. where it was burning—allowing Ops to trigger lateral transfers before stockouts occurred.

MAXIMUM YIELD

We turned a logistical gamble into a controlled operation. By moving inventory from cold stores to hot stores mid-season, we maximized the yield on every unit produced. Leadership protected their margins and ensured that when a customer walked in to buy, the product was on the shelf.

"We didn't just track sales; we engineered the flow of inventory to ensure we captured every dollar of demand."

— Director of Retail Operations, Hickory Farms